Sachet Manufacturing

WE ALSO OFFER BLENDING AND SECONDARY PACKING SERVICES

When looking for a UK sachet filling company, we are the experts, producing up to 15 million sachets a year.

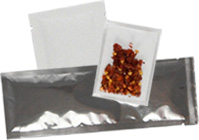

We manufacture 3–4 side seal pillow sachets for the food, nutraceutical and health & beauty industries.

Working from a BRC AA accredited factory in Merseyside, our focus is on quality every step of the way. Find out more about our food safety requirements here

We provide competitive prices & leadtimes. Our helpful team provide high levels of customer satisfaction with our sachet filling service.

- Wide range of food-safe powders & small grains.

- Low viscosity, ambient, food-safe liquids.

- Doses >2g (dry fill) or >5ml (liquid fill).

Our sachet filling services include:

- Range of laminate options to protect your product.

- Flexible sizes of sachets.

- Printing of batch & BBE date on every sachet.

- Safety first - rigorous quality checks & metal detection on sachet lines.

- We can also provide powder blending & secondary packing.

Different Sizes

Different Materials

Plain or Printed

Suitable for Powder

Suitable for Liquid